HORIZONTAL CYLINDRICAL STEAM STERLIZER

HORIZONTAL CYLINDRICAL STEAM STERLIZER Specification

- Feature

- Highly Efficient

- Voltage

- 220-240 V AC

- Core Components

- Chamber, Steam Generator, Control Panel, Door

- Power Source

- Electric

- Accuracy

- 100 %

- Model No

- HCSS-120

- Measurement Range

- 0â2.5 kg/cm² (Pressure Gauge)

- Frequency

- 50 Hz

- Capacity

- 78 liters

- Temperature Range

- 121°C to 134°C

- Automation Grade

- Semi-Automatic

- Equipment Materials

- Stainless Steel (Inner chamber & Outer body)

- Type

- Horizontal Cylindrical Steam Sterlizer

- Usage

- Laboratory

- Dimension (L*W*H)

- 1200 mm x 500 mm x 550 mm

- Weight

- Approx. 120 kg

About HORIZONTAL CYLINDRICAL STEAM STERLIZER

HORIZONTAL CYLINDRICAL STEAM STERLIZER

APPLICATIONS : -

Superior Chamber Design

The sterilizer boasts a mirror-polished stainless steel inner chamber (400 mm x 950 mm) with a generous 78-liter capacity. Paired with advanced glass wool insulation, these features minimize heat loss while ensuring thorough sterilization, making the unit ideal for laboratories and medical facilities requiring reliable and consistent performance.

Comprehensive Safety Mechanisms

User safety is prioritized via a radial locking lid system, pressure release valve, and automatic low water cut-off. These core features work together to prevent accidental operation under unsafe conditions and help maintain a safe operating environment in every use.

Efficient and Accurate Sterilization

The sterilizer operates at 121C to 134C with a 4 kW immersion heater, maintaining accuracy up to 100%%. Its mechanical timer and audible alarm ensure precise cycle control, while both automatic and manual steam release options enhance workflow flexibility for users in demanding clinical, research, or industrial environments.

FAQs of HORIZONTAL CYLINDRICAL STEAM STERLIZER:

Q: How does the radial locking system enhance the safety of the sterilizer?

A: The radial locking system secures the sterilizers door firmly, preventing accidental opening during operation. This not only maintains chamber pressure but also safeguards users from steam exposure and related hazards during the sterilization process.Q: What is the typical sterilization cycle time, and how can it be monitored?

A: The standard sterilization cycle runs for 15 to 30 minutes. You can monitor and control the cycle duration using the mechanical timer with an audible alarm, which notifies users when the process is complete.Q: When should the water level be checked, and how does the low water cut-off work?

A: The water level should be checked before starting each cycle. The automatic low water cut-off feature will halt operation if the water falls below the required level, preventing heater damage and ensuring reliable sterilization every cycle.Q: Where can this sterilizer be most effectively used?

A: This model is suitable for medical facilities, research institutions, hospitals, and microbiology laboratories. Its robust build, safety measures, and capacity make it an excellent choice in settings requiring frequent and reliable instrument sterilization.Q: What process does the sterilizer follow to ensure effective sterilization?

A: The unit builds pressure up to 1520 psi and raises chamber temperature to 121C134C. Steam penetrates the load, eliminating microorganisms. The process concludes with either automatic or manual steam release, guaranteeing thoroughly sterilized instruments.Q: How is the unit installed and powered?

A: Installation requires only a single-phase electric connection (220240 V AC, 50 Hz). Its compact dimensions and 120 kg weight also allow for straightforward placement in most laboratory or clinical settings.Q: What are the primary benefits of using this horizontal cylindrical steam sterilizer?

A: Key benefits include fast and efficient sterilization, minimized heat loss, user safety through advanced features, precise operation with 100%% accuracy, and compliance with ISI and CE standardsmaking it a dependable choice for routine sterilization tasks.

Price: Â

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BIOTECHNOLOGY, MEDICAL, HEATING & COOLING EQUIPMEN Category

HIGH TEMPERATURE DELUXE OVEN

Type : High Temperature Deluxe Oven

Core Components : Heating Element, Control Panel, Insulation

Equipment Materials : Powder Coated Mild Steel / Stainless Steel

Feature : Highly Efficient

Usage : Laboratory

Automation Grade : SemiAutomatic

ROTARY SHAKER TABLE TOP MODEL

Type : Rotary Shaker Table Top

Core Components : Motor Platform

Equipment Materials : MS powder coated

Feature : Variable speed control

Usage : Laboratory mixing/shaking

Automation Grade : SemiAutomatic

BLOOD STORAGE CABINET

Type : Blood Storage Cabinet

Core Components : Compressor, Digital Display Controller

Equipment Materials : Stainless Steel/ Mild Steel

Feature : Highly Efficient

Usage : Laboratory

Automation Grade : SemiAutomatic

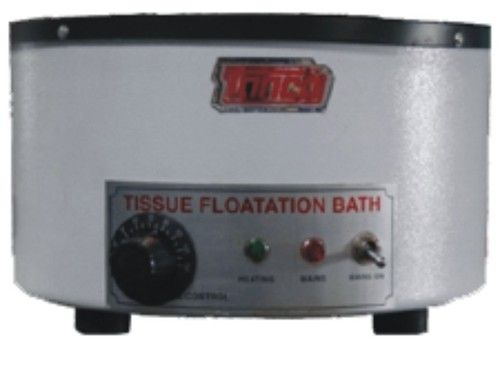

TISSUE FLOTATION BATH

Type : Heated Water Bath

Core Components : Heating Element, Temperature Controller, Digital Display

Equipment Materials : Stainless Steel Interior, Powder Coated Exterior

Feature : Highly Efficient

Usage : Laboratory

Automation Grade : SemiAutomatic

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry