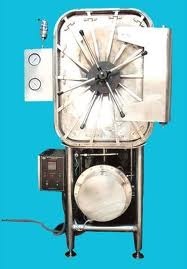

Horizontal Autoclave

Horizontal Autoclave Specification

- Type

- Rectangular horizontal autoclave

- Chamber Size

- 1000 x 500 x 500 mm

- Chamber Thickness

- 68 mm SS304

- Outer Size

- 1600 x 700 x 1700 mm

- Compressed Air

- 6-8 bar

- Door Type

- Horizontal sliding

- Design Pressure

- 2.1 bar

- Working Pressure

- 1.2 bar

- Design Temperature

- 139C

- Heat Uniform

- 2C throughout the chamber

- Insulation

- High-density mineral wool

- Net Weight

- Approx. 700 kg

- Recording Parameters

- Digital auto printout for temperature/time

- Spraying Mode

- Uniform spray through multiple nozzles

- Outer Trolley

- Included, SS304 construction

- Inner Trolley

- Included, perforated SS304 trays

- Spraying Piping

- Stainless steel seamless pipes

- Steam

- External saturated steam (0.30.4 MPa)

- Sterilizing Temperature

- 121C

- Working Temperature

- 121C (standard), programmable

- Sterilization Time

- 30-60 min adjustable

- Temperature Scope

- 105C to 134C

- Piping System

- Professional integrated piping

- Valves

- Safety, Air release, Vacuum breaker, Steam inlet

- Power Consumption

- 36 kW, depending on size

- Buzzer System

- Integrated for cycle completion

- Drainage System

- Auto/Manual selectable

- Chamber Material

- SS 304/316

- Sterilization Method

- Steam-sterilization with rotary spraying

- Temperature Sensor

- PT-100 Sensor

- External Finish

- Powder Coated MS or SS Covering

- Chamber Finish

- Mirror Polish

- Shelf Racks

- Adjustable/Removable

- Display

- LED or LCD Touchscreen

- Installation Type

- On-floor installation

- Data Logger

- Optional USB or printer output

- Door Safety Mechanism

- Interlocking safety system

- Operating Voltage

- 220V/380V AC, 50 Hz

- Vacuum System

- Integrated Vacuum Pump

- Water Supply

- Automatic/Manual

- Gasket Material

- Silicone/EPDM (food grade)

- Control System

- Microprocessor based programmable system

- Service Access

- Side service panels for maintenance

- Pressure Gauge

- Bourdon Type

- Cycle End Alarm

- Available (audio-visual)

- Packaging

- Export quality wooden crate packaging

About Horizontal Autoclave

Horizontal Autoclave

Horizontal autoclave (Cylindrical) Triple wall with

Pressure switch & water cutoff

(Triple walled with Steam Jacket).

The autoclave is mounted on a Mild Steel tabular stand. The autoclave Chamber & steam jacket are made of 14 SWG. Stainless steel, Outer shell which serves as a cover is made of stainless Steel. Steam jacket allows dry sterilization. Hinged door is made of stainless steel. Radial Locking arms prevent opening of the door while Steam is inside the chamber. Autoclave is fitted with neoprene gasket; steam is generated in a separate boiler which is placed below the main body. Multiport valve is provided for Steam, dry sterilization & steam exhaust.

Autoclave is fitted with easily replaceable heaters and water level indicator. Autoclave holds pressure at selected point between 10 to 20psi +/- 3 psi. Pressure control has markings which are approximate; the actual pressure is as shown by the pressure gauge. Hydraulically tested at 40psi. Fitted with safety valves pressure is as shown by the pressure gauge. Hydraulically tested at 40psi. Fitted with safety Valves pressure gauges, steam release valve, steam trap, and one tray.

Advanced Sterilization Technology

This autoclave utilizes steam sterilization with rotary spraying, ensuring uniform exposure across all instrument surfaces. The combination of a PT-100 temperature sensor, integrated vacuum system, and programmable microprocessor guarantees precise and consistent sterilization results for demanding applications.

User-Friendly Operation and Safety

Equipped with an LED or LCD touchscreen, the system offers simple program selection and status monitoring. Door interlock safety mechanisms, auto/manual water supply, and an integrated alarm system ensure safe operation. Maintenance access is streamlined with side service panels.

Flexible and Durable Design

The chamber, constructed from SS304/316 with a mirror polish, resists corrosion and supports adjustable/removable racks and trolleys. External coverings in powder-coated MS or SS and high-density insulation enhance durability. Professional piping and seamless spraying systems maximize performance and longevity.

FAQs of Horizontal Autoclave:

Q: How does the integrated vacuum pump system enhance the sterilization process in the horizontal autoclave?

A: The integrated vacuum pump efficiently removes air from the chamber before steam injection, ensuring optimal steam penetration and uniform temperature distribution, which results in thorough sterilization of all chamber contents.Q: What benefits do the microprocessor-based programmable controls offer for the user?

A: The microprocessor-based programmable controls allow users to customize and automate sterilization cycles, enhance process accuracy, and offer real-time cycle monitoring via touchscreen or LED/LCD display. This leads to greater flexibility, operational efficiency, and reliable sterilization outcomes.Q: When should the cycle end alarm and buzzer system be utilized during operation?

A: The audio-visual cycle end alarm and buzzer automatically notify users as soon as a sterilization cycle completes, ensuring timely removal or further handling of items, which is especially important in busy laboratory or clinical settings.Q: Where can this horizontal autoclave be installed, and what installation considerations are required?

A: This autoclave is intended for on-floor installation in laboratories, healthcare facilities, or industrial sites. Proper installation entails access to a 220V/380V AC power supply, external saturated steam source, water connection, compressed air (6-8 bar), and adequate space for side service panels and safe operation.Q: What is the process for maintaining or servicing the autoclave?

A: Routine maintenance involves periodic cleaning of chamber surfaces, gasket inspections, and system checks, all made easier by the accessible side service panels. Professional servicing ensures the integrity of the vacuum, control, and spraying systems for continued performance.Q: How is data recorded and logged during the sterilization process?

A: Cycle parameters such as temperature and time are digitally logged, with options for USB export or automatic printer output. This documentation meets regulatory standards and supports traceability for quality assurance and record-keeping.Q: What advantages does the adjustable/removable shelving and trolley system provide?

A: Adjustable/removable shelf racks and included trolleys enable flexible loading configurations and easy transfer of instruments, maximizing chamber use while accommodating items of various sizes or shapes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in AUTOCLAVES Category

Table Top Autoclaves

Working Pressure : 0.22 Mpa

Valves : Safety valve, exhaust valve

Heat Uniform : 1C

Working Temperature : 105C 134C

Door Type : Manual single door

Chamber Size : 385 x 250 mm

Cement Autoclaves

Working Pressure : 2.1 kg/cm

Valves : Pressure and safety release valves fitted

Heat Uniform : 2C

Working Temperature : Up to 132C

Door Type : Hand wheel type locking system

Chamber Size : 200 x 600 mm

Horizontal Rectangular Autoclaves

Working Pressure : 1.2 Bar

Valves : Automated ball valves for inlet & outlet

Heat Uniform : 1C throughout chamber

Working Temperature : 121C

Door Type : Horizontal sliding/Manual or Automatic

Chamber Size : 1000 x 600 x 600 mm (customizable)

Horizontal Autoclaves

Working Pressure : 1.2 2.2 bar

Valves : Driven by pneumatic or electric actuator, SS316

Heat Uniform : 1C across chamber

Working Temperature : Up to 128C continuous

Door Type : Horizontal sliding or radial arm locking door

Chamber Size : 1100 x 500 x 500 mm (other sizes on request)

GST : 06AOXPS4632P1ZW

|

|

SINGHLA SCIENTIFIC INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry